Business

AP Systems, moving forward into the world with a passion for endless research and technological developments

Laser Application Technology

We use laser to provide client companies with core equipment used in the AMOLED and Flexible OLED display process.

- Annealing equipment is used to crystalize a-Si into p-Si in the AMOLED process, and also used to separate glass boards by coating with polyimide (PI) to form a film on the glass board in the Flexible OLED process.

- Micromachining equipment is laser process equipment that can manufacture Fine Metal Mask using materials, and can realize patterns up to UHD (Ultra-HD) level.

- Cutting equipment is used to cut glass and the board of the flexible display.

- Annealing

- Excimer Laser Annealing

- Laser Lift-Off

- Micro-machining

- Fine Metal Micro-machining

- Cutting

- Glass Laser Scribing In-line System

- Film Laser Cutting

- Excimer Laser Annealing

- Laser Lift-Off

- Fine Metal Micro-machining

- Glass Laser Scribing

In-line System - Film Laser Cutting

Excimer Laser Annealing

KORONA™ LTP

It is a laser thermal process system designed for Low Temperature Poly Silicon Crystallization (LTPS). We have integrated world-class laser, optics technology, and chamber technology to form high quality LTPS TFT (Thin Film Transistor). It is applied in AMOLED backplane and LTPS LCD fields.

Technology

Irradiate Excimer Laser on the TFT board with a-Si film to form Poly-Si film.

Specification

| Laser Type | Excimer Laser |

|---|---|

| Laser Wavelength | 308nm (XeCl) |

| Laser Repetition Rate | 600Hz |

| Laser Pulse Energy | 1J, 2J, 4J |

| Laser Uniformity | Long Axis (2σ): ≤ 1.8% (@96%) Short axis (2σ): ≤ 3.0% (@96%) |

| Stage Type | Single Plane or Stack Plane |

| Stage Position accuracy | X axis: <±2um Y axis: <±2um |

| Process Environment | ATM & N2 Atmosphere |

| Software | Easy Cluster™ |

| Safety Certification | CE, SEMI, S-Mark |

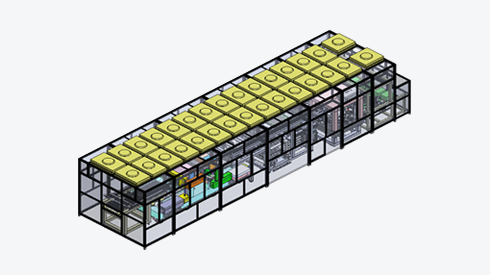

Laser Lift-Off

KORONA™ LLO

It is a Laser Lift-Off system designed for Flexible Display. Using laser, optics technology, and process modules, Carrier Glass is separated from the board to manufacture thin film devices. It is a core facility in the flexible display manufacturing process.

Technology

Irradiate Excimer Laser to separate polyimide (PI), which is a plastic material, formed on the glass board.

Specification

| Laser Type | Excimer Laser |

|---|---|

| Laser Wavelength | 308nm (XeCl) |

| Laser Repetition Rate | 600Hz |

| Laser Pulse Energy | 1J, 2J |

| Laser Uniformity | Long Axis (2σ): ≤ 1.8% (@96%), Short axis (2σ): ≤ 3.0% (@96%) |

| Stage Type | Single Plane or Stack Plane |

| Stage Position accuracy | X1, X2 axis: <±4um, Y1, y2 axis: <±4um |

| Process Environment | ATM |

| Software | Easy Cluster™ |

| Safety Certification | CE, SEMI, S-Mark |

Fine Metal Micro-machining

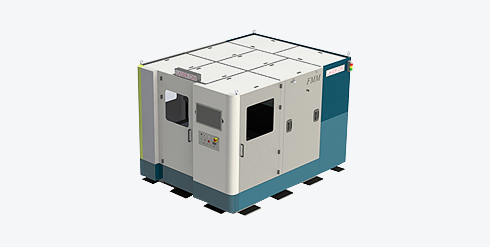

KORONA™ FMM

It is a type of laser process equipment that can manufacture Fine Metal Mask for screens, which are used for the deposition of organic matters in each RGB when manufacturing OLED displays. It is a combination of process technology that can use lasers with a width of ultra-short pulse and precisely designed optics system in optimal ways, in which ablation and patterning of hard metal is possible.

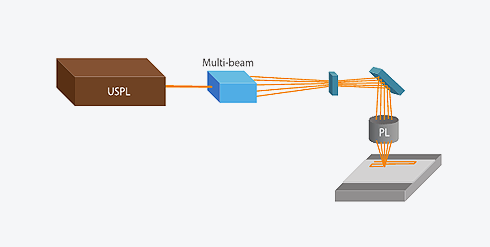

Technology

To the Femtosecond Laser (fs Laser), which has an extremely short pulse width of 1/1 quadrillion sec. (10-15 sec.), a special Mask projection optic system, which can make Multi-beams and precise shapes at the same time, has been combined. In addition, Invar matter, which is a precise metal used as a material for FMM, has been incorporated to the process technology, which can minimize the effect from the heat that could occur during the reaction with laser.

Specification

| Substrate size | 300*300mm2 |

|---|---|

| Motion | 2 axes air-bearing stage |

| Substrate handling | Electrostatic chuck |

| Position accuracy | 1um |

| Multi-beam | 50 |

| Pattern resolution | UHD |

| Particle control | Debris suction |

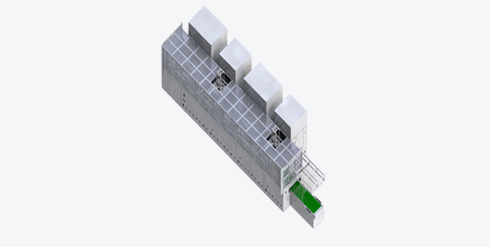

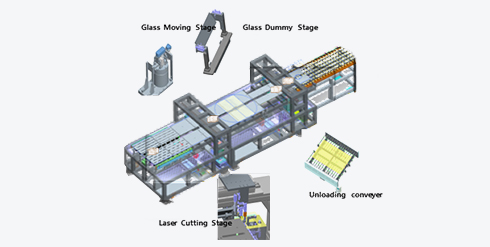

Glass Laser Scribing In-line System (Cell Cut)

KORONA™ LSS

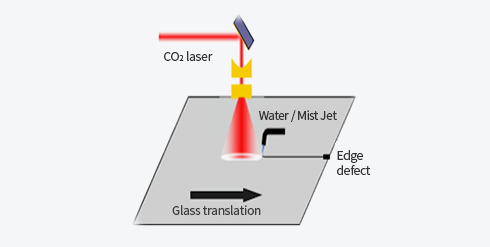

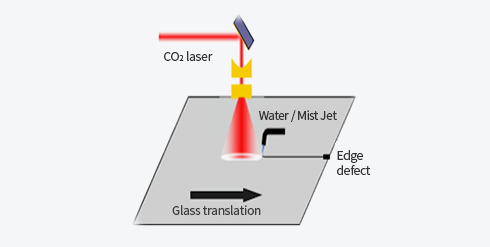

It is equipment applied to the FPD (Flat Panel Display), and in the Cell stage of coalescence stage between TFT and CF (Color Filter), the equipment cuts the upper board/lower board using CO2 Laser.

Technology

KORONA™ LSS is a Glass Cell Cutting System. High precision laser, optics technology, and precision control technology are provided, and the system is composed of Loader/Unloader, Auto Breaker, and Laser Scriber.

Specification

| Laser Type | CO2 Laser |

|---|---|

| Laser Wavelength | 10.6um |

| Output Power | 70W |

| Laser Repetition Rate | 0 ~ 100kHz |

| Laser head position accuracy | ≤±5um |

| Laser Uniformity | ≤2% |

| Stage Type | Single Plane or Stack Plane (Al6061 + Hard Anodizing) |

| Stage Flatness | ±50um |

| Process Environment | ATM |

| Software | Easy Cluster™ |

| Safety Certification | CE, SEMI, S-Mark |

Glass Laser Scribing In-line System (Array Cut)

KORONA™ LAC

It is equipment applied to the FPD (Flat Panel Display), and after Array process is finished, this equipment cuts the Glass into ½ or ¼ size using CO2 Laser.

Technology

KORONA™ LAC is a Glass Cutting System. High precision laser, optics technology, and precision control technology are provided, and the system is composed of Loader/Unloader, Auto Breaker, and Laser Scriber.

Specification

| Laser Type | CO2 Laser |

|---|---|

| Laser Wavelength | 10.6um |

| Output Power | 100 ~ 400W |

| Laser Repetition Rate | 0 ~ 100kHz |

| Laser head position accuracy | ≤±5um |

| Laser Uniformity | ≤2% |

| Stage Type | Single Plane or Stack Plane (Al6061 + Hard Anodizing) |

| Stage Flatness | ±50um |

| Process Environment | ATM |

| Software | Easy Cluster™ |

| Safety Certification | CE, SEMI, S-Mark |

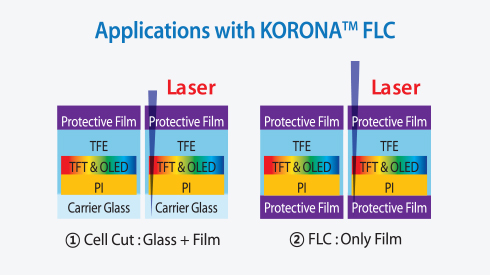

Film Laser Cutting

KORONA™ FLC

It is a laser Cutting system designed for various Films used in the Flexible Display. High precision laser, optics technology, and automation technology are integrated to cut and inspect the products. It is a process facility essentially recruited in the Flexible Display manufacturing process.

Technology

Laser is irradiated to the Flexible Film to perform precise Device Cutting.

Specification

| Laser Type | DPSSL / CO2 |

|---|---|

| Laser Wavelength | 355nm(UV), 532nm(Green), 1064nm(IR), 9.6um |

| Cutting Accuracy | ≤ ±50um |

| Model change | Working table(Auto change ≤ 1hour) |

| Stage Type | Single Plane or Stack Plane |

| Process Environment | ATM |

| Software | Easy Cluster™ |

| Safety Certification | CE, SEMI, S-Mark |